As the COVID-19 pandemic continues to affect thousands across Canada, a shortage of Personal Protective Equipment (PPE) for health care workers treating virus patients has been at the forefront of political and medical discourse.

To help meet some of the demands, Camosun College has partnered with AP Plastics to produce more than 9,000 medical grade face shields for Island Health workers.

“The innovative work of the team at Camosun Innovates to support the needs of health care professionals with high quality and effective face shields is an example of how we are all in this together,” says Sherri Bell, President of Camosun College.

“We expect that the new design and enhanced manufacturing process will support faster production methods to be replicated locally and across the country.”

The team working on the project is led by Dr. Richard Gale, with Applied Research Technologist Matthew Zeleny serving as the coordinator of all COVID-19 response activities.

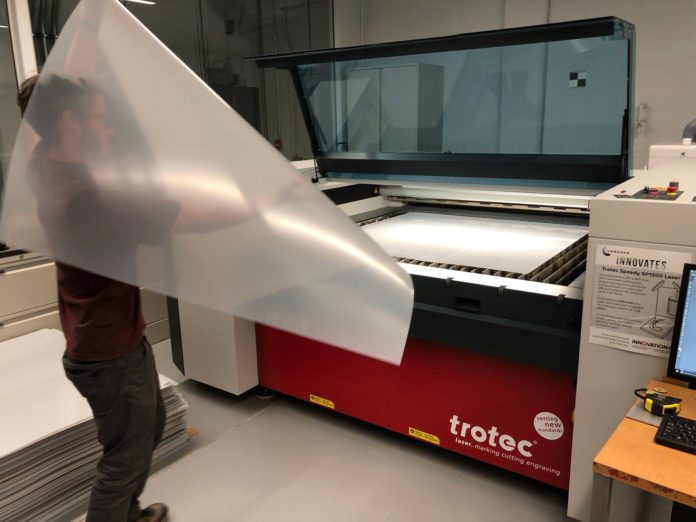

Zeleny realized that 3D printing would not be able to meet the growing demands and, after consulting with Island Health and AP Plastics, designed a new flat-pack version of face shields.

This new design could be produced by the college’s facilities at the Babcock Canada Interaction lab at a rate of 90 per hour instead of 10 per day that is the capacity of the industrial 3D printer.

“I started with a speculative design and then took the specs required by Island Health and fit them to the manufacturing standards of the machines and materials we had available,” explains Zeleny.

“The shield is designed with a built-in buckle so it’s adjustable and compatible with a wide range of strap materials for the greatest flexibility in real-world conditions.”

These masks will be produced using high quality modified Polyethylene Terephthalate (PETG) and production will begin this week at Camosun’s Interurban campus using the research team’s laser cutting machine.

Industry partner, AP Plastics, will also be restructuring their facilities in Calgary in order to better produce Zeleny’s design of face masks across Canada.

By the end of May, the company expects to be able to produce 4,000 face shields per day.

During his press conference on Thursday morning, Prime Minister Justin Trudeau announced that Canada received a shipment of over 1 million protective masks for frontline health care workers.

This new shipment arrives in addition to the 10 million masks that have come in over the last few days.

The federal of government has also ordered hundreds of thousands of face shields from Bauer Hockey, after the company restructured to produce medical grade PPEs for health care workers.

See all the latest updates about the global COVID-19 pandemic on Vancouver Island

According to the latest updates, there are 1,066 cases of COVID-19 in British Columbia, including 72 on Vancouver Island.

In good news, a total of 606 people have now recovered from the virus in B.C.

The BCCDC has set up a 2019 novel coronavirus telephone information line at 1-833-784-4397 for those who have further questions about this disease.

Anyone concerned that they may have been exposed to, or are experiencing symptoms of the novel coronavirus, should contact their primary care provider, local public health office, or call 8-1-1.

The Province has also created the 1-888-COVID-19 line to connect British Columbians needing non-medical information about the coronavirus pandemic.

As of the time of publication, the total number of COVID-19 patients worldwide has risen to 983,635.

Over 50,300 people have died from the illness and 206,290 have made a full recovery.